Our company in collaboration with a designer and manufacturer of industrial packaging machinery company is able to equip the food industry factories all over the world with the latest machinery. The company started its fundamental experience of servicing and optimizing various production machineries and packaging foreign canned food in 1972.

Having 35 years of experience and employing skilled technicians and experts in manufacturing of production line machineries and packaging compote, various canned food, jam, honey, pickles, olive, Zeitoon Parvardeh (olive spread with pomegranate, walnut …), mayonnaise sauce, ketchup sauce, stone fruits puree, fruit juice, and packaging lines of manufacturing factories and workshops at present time, the company has managed to achieve a good standing in domestic and foreign markets.

Regarding our fundamental experience, we provide the manufacturing factories with a wide range of services from consultancy to operation, supplying spare parts, guaranteeing production time and production-related issues. Basic repairs of various foreign capping machineries are made under guarantee and their spare parts are produced.

It is worth mentioning, our partner company with more than forty years of experience as one of the most prominent manufacturers of machinery in the modern food industry of the country and considering the presence in global markets, has standards ISO 9001-2015, CE Europe and Iran standard.

Our Products

AUTOMATIC 4-HEAD SEAMER

can seamer machine as one of the main machines in the line of Factory with 4 head system, is special for seaming round metal cans of 100 g to 1200 g or spans 52-99 mm diameter for packing in meat and non-meat canned lines, as well as Chemical industry, paint, oil, resin and lubricants can be used.

Capacity: Up to 9,000 cans per hour – Variable round

The seamer machine is equipped with a remote control and the production speed is simply controllable, and since it has a production line control circuit, the controller can easily control the speed of production. Equipped with 2 digital counterparts, nominally and instantaneously, in minutes, for the first counter of the command of the production manager to be registered to the device, ie, in minutes, a few cans, and the second counter, records the output of the can of the device, that is, the ability to What’s the line in a minute, and this difference in the rate of disability of the production line in relation to what the director wanted to be.

AUTOMATIC 3-HEAD SEAMER

Automatic 3 head seamer machine, as one of the main machines in packaging lines, edible oils, as well as chemical industry including industrial paints and industrial oils, resin and lubricants with 3-head system, specially designed for holding round metal cans of a size 1000 grams to 5000 grams or openings of diameter 99 to 185 mm can be used.

• Capacity: Up to 1800 cans per hour – Variable round

SEMI-AUTOMATIC SEAMER

Semi-Automatic seamer ideal for canned and tomato paste products in the food and paint industries, and the engine oil and grease industries to cover the size of the spans 52 to 185 mm for round metal cans with simple door and easy door opening. Gets

• Capacity: 800 cans per hour

• Precise and reliable operation

• Very low cost in the design and construction of this device

SEMI AUTOMATIC UNDER VACUUM SEAMER

semi automatic under vacuum SEAMER It provides a perfect solution for the survival of brittle products and similar products with a vacuum system in metal cans.

• Capacity: 500 cans per hour

• Precise and reliable operation

• Very low depreciation

ALEPPO SEAMER

This machine is used for capping rectangular or large round cans or in the so-called Aleppo and will be placed in the production and packaging lines of food such as cucumber, olive, cheese, oil and so on.

Advantages:

Easy to operate

Acceptable efficiency

Increase production efficiency

Supply the product in larger volumes

Sturdy structure and beautiful design

Material of steel 304

MANUAL SEAMER

The pedaling seamer machine is one of the simple manual machinery, yet practical, machine tools for seaming all kinds of round metal cans from 52 to 183 mm in diameter for easy open doors and simple with a capacity of 500 cans per hour.

FILLER MACHINE 3-NOZZLE

Filling machine 3 nozzles is a line-type intermediate device ideal for producers of tomato paste filling, eggplant caviar and fruit pulp with a capacity of 4,500 number per hour in metal cans in volumes from 400 g to 1,000 g. .

• Usage: Suitable for a variety of fruit pulp, eggplant caviar and so on

• Equipped with a PLC and monitoring system, and the controller can easily control the movement of the device manually and automatically.

• Sustainable structure (made of stainless steel)

• Precise and reliable operation

FILLER MACHINE ONE NOZZLE

Single-nozzle filling machine with 2 linear systems, and this device is suitable for manufacturers with low capacities and limited capacity to fill thick and semi-thick liquids.

• Easy and stable structural performance (made of stainless steel)

• Precise and reliable operation

AUTOMATIC MEAT FILLER MACHINE

The automatic filling machine of meat with 304 stainless steel design is one of the main machines in the line of canned meat production lines, especially for filling meat in cans from 120 g to 180 g with a diameter of 83 mm.

SALT -POURING MACHINE

The Salt pouring machine is used in meat canning lines and automatically adds salt to the product in cans. Note that its main use is in canned tuna lines.

Advantages:

Workforce reduction

Accuracy and prevention of human error

Increase product health

OPERATOR’S FILLING LINE, ALONG WITH RECEIVER’S ELEVATOR

Operator’s filling line, along with receiver’s elevator.A collection is designed to fill products such as tomatoes and eggplants and the like in metal containers of 1000 to 5000 grams with automated filler restrictions.

AUTOMATIC FILLER MACHINE

The automatic filling machine is fully automatic for filling cucumber, olives and garlic in glass and cans it be can be used in the processing lines for salty cucumber, pickles and salty olives.

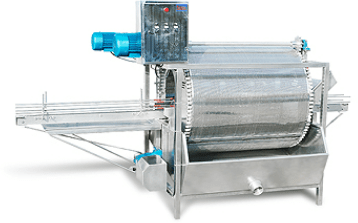

BLANCHER

This machine is ideal for pre-cooking products such as beans, chickpeas, lentils and more with a capacity of one ton per hour in the processing of non-meat production lines.

Blanching or blancher in the food industry will be used to inactivate or disable enzymes. The relatively gentle heat process used in blanching inhibits for the enzymes from activity.

In this process, the crops are affected by boiling water or water vapor for a short time and are quickly put in cold water so that they do not become cooked and their appearance does not change appreciably. The device where the blanching process is performed is called blancher. Blanching generally has two ways with boiling water, steam and then cooling. Blanching Benefits:

• Transparent food coloring

• Disinfectants

• Pre-cooked products

• Inactivate enzymes

• Reduce baking time

HELICAL BLANCHE MACHINE

Helical blanching machine Blanching operation designed with indirect steam heating for products such as compote, puree and some vegetable for a short time. The main task of this is to inactivate bacteria and enzymes, which can otherwise cause rapid degradation of quality. The other two desired effects are the removal of air and gases in the product and reducing the product volume. In this blender, the product moves in a spiral and twisting manner as the product blends in the spiral motion.

Increase product quality

Increase production speed

SEMI-AUTOMATIC BLANCHER (FRYER)

Blanching is a controlled heating process similar to pasteurization and is used in the processing of fruit juices, fruits and vegetables, and the blanching machine uses semi-automatic blanching or pre-cooking of the product before final baking with the intervention of the operator. Because of its semi-automaticity, it has less capacity and will be used for low-capacity production lines. In some cases, oil may be used instead of boiling water, which will change its use and fry the product.

Advantages:

Double application

High efficiency

Increase product quality

CARROTS PEELER

Carrot Peeler by Brush is the ideal precision peeling machine and without waste with 9 circulate brushes with a capacity of 1.5 tons per hour.

• Benefits: Easy operation – Tight structure (Made of stainless steel 304) Ease of washing and cleaning

PEELER MACHINE

The peeling machine can be used for peeling products such as carrots, potatoes and onions. The mechanism of this peeling machine, along with the centrifugal pressure of water, performs simultaneous primary washing and peeling.

• Capacity of 1000 kg per hour

• Optimal, powerful and waste-free operation

• The structural material of this machine is steel 304

TAIL-STUCK

Tail-stuck machine, used for tail stucking fruit such as sour-cherry, cherry and olive as well as cucumber flowering in jams, compote and canned olives and cucumbers.

Advantages:

• Sturdy structure (made of stainless steel 304)

• Ease of washing thoroughly

• Easy and accurate operation without waste

CORE-STOCK

The pitter for sour cherry is a suitable method for pitter fruit such as cherries, sour cherries and blueberries to produce jams and juices in food processing plants. The pitter for sour-cherry nucleation using two shoulder and plastic drums with separating blades, it can stocking core.

Advantages:

Easy and accurate operation without waste

Sturdy structure (made of stainless steel 304)

Ease of washing thoroughly

SLICER MACHINE

This machine is ideal for carrot jam and season salad producers, so that it can handle a ton of carrots in an hour, without conducting or squeezing, on this device, the installation and installation of 4 mm to 18 mm mesh screens It is possible.

• The material used in the device is 304 stainless steel.

• The quality of graving the product in terms of size and dimensions, as well as the appearance is very high.

SLICER MACHINE

Vegetables slice machine is ideal for pickle and salad producers, which can be used for crushing celery, lettuce, cabbage, cauliflower, cucumber, carrot, green beans, peppers and the like.

• Precise and reliable operation with smooth and even slices

• Ability to cut arbitrary size

• Very low depreciation in design and engineering, and ultimately increased life span of the machine

• High quality and long life blades for excellent material

MUSHROOM SLICER MACHINE

Mushroom slicer: Specialty raw and blanched mushrooms used in non-meat and meat processing and slicing lines that slice the mushrooms into sheets.

Advantages:

• High efficiency

• Reduce staffing

• Reduce production waste

• Sturdy structure and beautiful design

• Steel 304

PASTEURIZER TUNNEL MACHINE

The sheet slicer is capable of cutting 4 mm and 6 mm thick sheets of fruit such as oranges, apples, kiwi, tomatoes, onions and the like and generally for fruit or fry drying and packaging lines. It is used to make and pack onions or pickles of seven fruits and blends.

Advantages:

• Increase product attractiveness

• Applied for fruit chips

• Facilitator

• Reduce workforce

• Increase productivity and productivity

CUBICAL SLICER MACHINE

Cubic slicer is a practical way to dimensions products such as carrots, potatoes and onions and more.. This machine is known as the Cubicle Machine or Slicer on the market.

• With German resistant blades with anti-corrosion and anti-corrosion properties

• Material used in this machine is steel 304.

• Capacity: 500 kg per hour

• Accurate and reliable operation

SLICER MACHINE

Cubical slicer machine: the output of which is cubic , suitable for products such as carrots, potatoes, eggplants, cabbage, etc. The capacity of this machine is lower than its rotary type and in the workshop. Low-capacity generating outputs are used.

Advantages:

• Reduce staffing

• Increase production efficiency

• Easy to use

• Increase product attractiveness

• Steel 304

AUTOMATIC SLICER MACHINE

Suitable automatic slicer: Used to slice various types of products (carrots, potatoes, eggplants, cabbage, etc.), spatially for different lines of the food industry.

Advantages:

• Increase efficiency

• Increase productivity

• Easy to use

• Steel 304

CARROT TOP AND TAIL CUTTING MACHINE

As the name implies, this machine is used for cutting carrot heads and bottom and is generally used for carrot washing and packaging lines, carrot juice production lines.

Advantages:

Increase production speed

Workforce reduction

Reduce human error

CARROT DEHYDRATION MACHINE

This machine is a convenient and efficient way to dehydrate carrots by blowing air through the fan for transfer to the machine and to the packaging. It is necessary to explain, usually in the factories than the speed of production that two or more machines in the washing and packaging line Carrots are used

WASHING AND ELEVATOR MACHINE

Washing and elevator Machine is a set of two washing machines and lifting machine that are combined to form this machine. This machine is used for washing products such as cucumbers, carrots, greens, etc. by rotating in the water and transferring it through the elevator to the next stage. And it will be of particular importance to the performance of later stages.

• Advantages:

• Wash and disinfect the product and increase product hygiene

• Reduce workforce

• Increase work efficiency

TYPES OF PRODUCT TRANSFER PUMPS

Food transfer pumps are made from stainless steel for food use for the food industry. The food pumps were designed to have all levels of the pump flat, eliminating the risk of bacteria being harvested. Depending on the need, temperature, viscosity of the liquid being used, different pumps are used.

This machine is used to transport large pieces of food with a reservoir. Adjustable suction and discharge speeds independently increase efficiency to allow a wide range of coarse-grained products to be pumped. Apparently, it is pumped and is mostly used for jams, olives, pickles, fruit purees.

• Advantages:

• Increase production speed and productivity

• Quality assurance of the finished product

• Reduce product damage and reduce maintenance costs

• High accuracy and precision performance

STEAM SHRINK LABELING MACHINE

Shrink Label Machine: Performs the job of gluing the label as well as the ring or sheaths around the door with the steam system.

Used for labeling glass containers and pet products for products such as jams, pickles, salty olives, pickled olives, cucumbers and similar products.

• Advantages :

1. Easy and accurate operation

2. Sturdy structure made of 304 steel

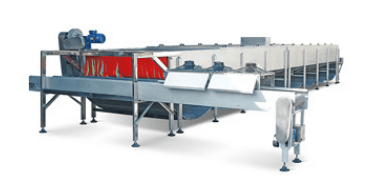

PASTEURIZER TUNNEL MACHINE

The pasteurizer tunnel unit forms a fully continuous unit in four heat zones (boiling zone, hot zone, cold zone and dry zone). Dimensions vary from 12 meters to 27 meters depending on the product.

• Design and structure of this machine is made of steel 304.

• The capacity of this machine varies from 2500 to 9000 glass or cans per hour depending on the capacity of the production line.

• Equipped with automatic temperature control in 3 heat zones with precision instrument control equipment

• Equipped with an alarm system for temperature control and internal traffic control of the tunnel

• Equipped with alarms for electrical and mechanical problems

• If no attention is paid to the warning system in any area, the tunnel will stop automatically and all entrances, including steam and other items, will be closed.

• Tunnel equipped with subsystems to increase the pasteurization time of 5kg dishes or products such as compote

• Polypropylene fiberglass tape with working temperature of 140 ° C

THE DATE PALM PASTE LINE

The date palm paste line is an interconnected unit capable of converting various types of dry and soft dates by the mechanism of heat, pressure and abrasion, core-stuck and conversion into date paste.

• Capacity: 300 kph

• The material used in this device is 304 stainless steel.

• Optimal and accurate operation

COOKING PLATFORM

The platform consists of a set of double wall tanks made of steel 304, equipped with horizontal mixers for the formulation, preparation and baking of products such as jam, pickles, caviar and olives. This platform has a central drain output that 4 tanks are attached to it, which can be either a single drain tank or a single tank for all four tanks.

WEIGHING AND PACKING MACHINE FOR VEGETABLES

Product Weighing and Packing Machine: Used for weighing and packing in plastic bags or boxes and used in washing and packaging lines of various products such as carrots, dried fruits and products.

• Advantages:

• Increase product health

• Determine product weight

• Reduced packaging error

• Practical and facilitating

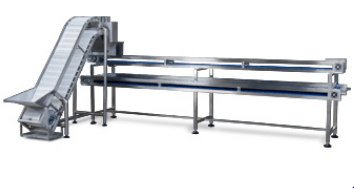

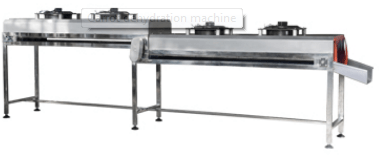

INSPECTION LINE

This special machine is used for receiving, raising and controlling products such as cereals, rice and similar products for canned food and industrial kitchens. This machine is one of the most important machines in automatic non-meat canned and canned food lines. It is a set of three machines that form a complete line and consist of the finest raw materials.

Advantages:

• Increase production speed

• Reduce workforce

• Increase the maximum productivity of raw materials

• Reduce human error

• Facilitator and Practitioner

Our Services

- ADVICE AND VISIT THE LINE

According to your request, we will take industrial advice from the first step to the results, and will visit the premises of the industrial unit and provide general advice at the site. In this way, the oldest industry experts will be used.

- AUTOMATION

- Improving the quality of finished and final products

- Increase production speed

- More accurate and faster quality control

- Reduce waste and dispose of products in production

- Increase the productivity of industrial units according to their investment level

- Raise the safety of manpower and reduce the employees mental and physical pressures

- Develop and increase the profitability of the entire product line

- Secure user and inappropriate non-stop and repeatability of activities and processes

- Fast support when stopping the production line

- INSTALLATION

We provide installation and commissioning services in a way that works as accurately as possible and in accordance with the customers opinion at the earliest opportunity.

• Precise design of machinery for installation and operation

• Fundamental planning of the plan based on economic production potential

• Proper timing for launching machines to market in accordance with the needs of the target market

• The presence of the company’s experts at the site to eliminate possible defects and achieve a proper start-up of production, with no shortages and more productivity than time, production and resources.

- REPAIR AND RESTORATION AND MAINTENANCE

– Increase the useful life of machinery and save on the purchase of new machines

– Increase the efficiency of machinery.

– Increased overall machine performance

– Decreased repairs of machinery.

– Preventing the spread of defects and possible defects

– Addressing minor deficiencies before requiring general repairs

– Preventing interruptions in production by replacing worn parts before the fracture and disabling the device and preventing damage caused by interruptions in operation.

– Increasing the workforce efficiency

– Reduced overall repairs and repetitions

– Improved product quality.

- SUPPLY PARTS

Our company in order to provide customer service better and solve needs in the shortest time provides parts for the machinery.

- SUPPLY OF LABORATORY EQUIPMENT

Our company supplies the necessary laboratory equipment for the food industry to train and use the tools needed for optimal use.

- SPECIAL ORDERS

If you have a new idea that is consistent with the production process in the food industry, and on the other hand, you want to make the project in an optimal economic framework and productivity. We can provide the platform for your idea. With the assistance of the technical experts, we have conducted the studies necessary to foster this idea, designing it and implementing it. At the end of this project, we will be supporting you.

More than 350 domestic brands in food industry are our customers and we have successfully designed and manufactured projects for them, including SHIRIN ASAL CO, SHAHSAVAND, HOSSEINI BROTHERS NUTS, CHINCHIN CO, etc.

Also we have a lot of successfully designed and manufactured projects for some countries such as Iraq, Afghanistan, Turkey, Germany, Kyrgyzstan, Turkmenistan, Georgia, Kazakhstan and Bahrain.